XMT-908P Series tprogrammable Temperature Controller

Get Latest Price| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 2 Piece/Pieces |

| Transportation: | Ocean,Land,Air,Express |

| Port: | NINGBO,SHANGHAI |

| Payment Type: | T/T,Paypal |

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 2 Piece/Pieces |

| Transportation: | Ocean,Land,Air,Express |

| Port: | NINGBO,SHANGHAI |

Model No.: XMT-908P Series

Brand: CJ

Control Typel: Digita

Control Method: Electronic Type

| Selling Units | : | Piece/Pieces |

XMT-908P Series programmable intelligent Temperature controller Temperature Instrument

Ⅰ、Main Technical Indexes

1、Basic error: ≤±0.5%F.S±1B

2、Cold end compensating deviation: ≤±2.0℃

3、Sampling period:0.5 second

4、Control cycle:relay output 2~120S , other is 2S.

5、Alarm output the drop in level:0.5 or 5

6、Relay output contact capacity:AC220V/5A (resistance load) or AC220V/0.3A (perceptual load)

7、Dring controllable pulse output:≥3V scope,≥50μS widthcontact with pulse when move to exceed zero

8、Driving solid relay signal output: driving electric current≥15mA, voltage≥9V.

9、Continuous PID : 0~10mA (load 500±200Ω), 4~20mA (load 250±100Ω),

or 0~5V (load≥100kΩ) , 1~5V (load≥100kΩ)

10、Power: AC90V~242V, 50/60Hz

11、Work environment: temperature 0~50.0℃, humidity≤85%RH, without corrode and strong electric radiation.

Ⅱ、Product code:XMT □ 9 □ 8 □ P (1) ⑵ (3) (4) (5)(6)

(1) Meter faceplate and Installation dimension(mm):

Blank: 160×80×130 156×76; A: 96×96×110 92×92;

D: 72×72×110 68×68; E: 48×96×110 44×92;

F: 96×48×110 92×44; S: 80×160×130 76×156;

G: 48×48×110 44×44

(2)Design serial number

(3)Alarm: “ 0”: no set alarm “ 1or2”: one alarm “5”: voice alarm

“3”: two group alarm (Alarm mode can be selected by the parameter ALP)

(4)Input signal: “8”: Free exchange of the input signal

(5)Control method: Blank: Relay contact; “G”: Solid state relay;

“A”: Zero passed trigger of controlled silicon; “ A3”: Three-phase over-zero trigger adjustment;

“ B”: Controlled silicon phase-shifted trigger; “C”: 0-10mA or 4-20mA constant electric current output;

(6)“P”:64 segment program(It contains 32 rise temperature segments and 32 constant temperature segments.)

Ⅲ、Panel schematic diagram(consult)

Ⅳ、Code setting mode

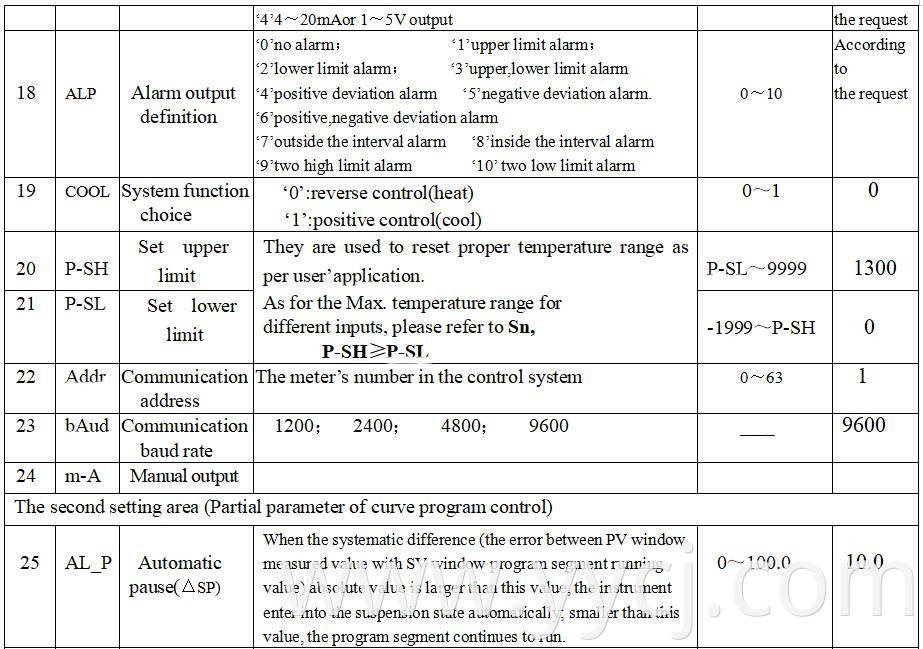

Time parameter :the third setting area(only use when with the print function)

5.1、The first setting area:

Press the SET key 3S enter into the first setting area, the meter will display the parameter code 1~23 in the window at the upper row and display the parameter data at the low row. In this time press the ▲、▼ or t key to adjust the parameter, then press the SET key to preserve. If within 10 seconds do not press every key then it will automatically to preserve the data and withdraw the setting.

The LOCK is electronics lock, when Lock=0, all the parameter can be revised; when Lock=1, only the “SP” can be revised; when the Lock>1, all the parameter can not be revised. But don’t set the Lock>50

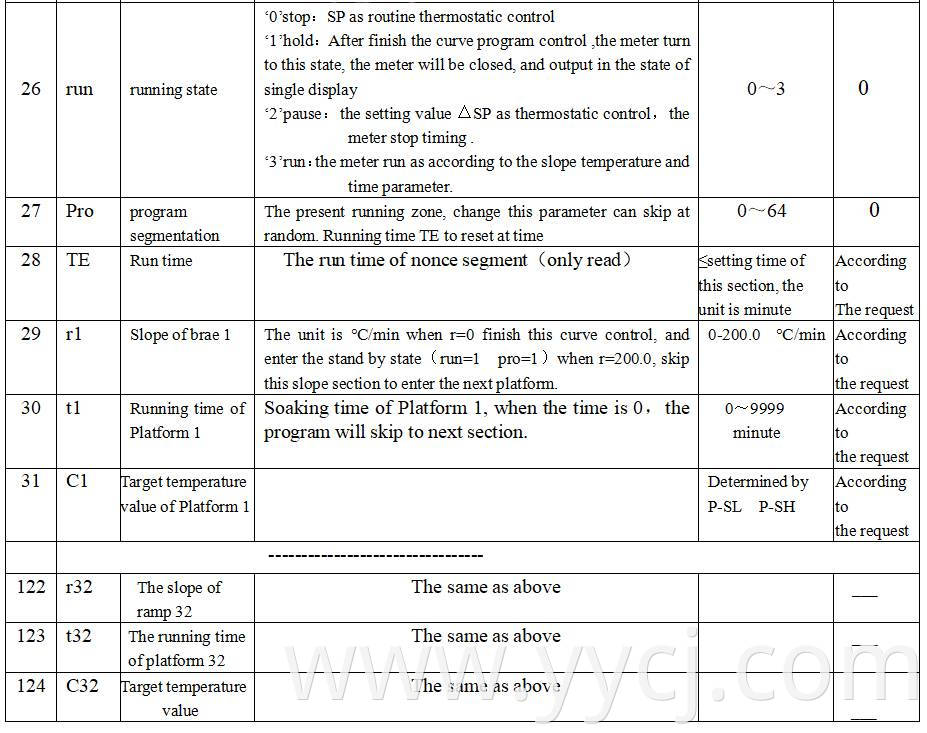

5.2、The second setting area (Partial parameter of curve program control):

Curve parameter setting area, press SET+3 Second to enter into the other operation is the same as above.

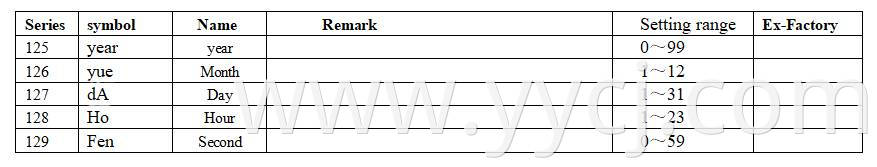

5.3、The third setting area (Time parameter):

When the power on, press SET+▲+▼key to enter into the setting area, the other is the same as above.

5.4、When run=0, The setting value amend(SP) :

Press the ▲ key 3 second to enter into the setting value amend area(SP), the other is the same as above.

5.5、Manual regulation:

When the meter is set up with the electricity, press the t key about 3S enter into the manual regulation, it will display “H” at the lower row, in this time can set the output power; press the t key about 3S again it will withdraw the manual regulation.

When the control object is valve, the manually operation value >50,and is co rotating,whereas is reversal,stable output duty ratio is 100%。

5.6、reposition: press t +▼key about 1 second, the program will reposition the first stage, run according to the running state.

5.7、Normal using ,it shows the measurement data in the window at the upper row and display the setting data SV at the lower row, press the▼ key it will display the main control output data, the first LED display “F”,latter three LED 0~100 output data.

5.8、Suspension and recycling operation :

When the instrument is in the normal operation, pressing ▲ key for 3 seconds program segment will enter into the suspension state, this time AM indicator light is flashing; pressing ▲ key for 3 seconds again, the program segment resume running. When the program segment finish running, then enter standby mode; pressing ▲ key for 3 seconds the program segment start to re-run from the first segment.

Ⅵ、Operation method of running curve program

1、Three work state of the meter

State of stop:when the meter is in the state of stop, the meter is used as the thermostatic control, the setting value is the basic setting value(SP),display in the window below, the running indicator light turn off.

State of running:

When the meter is in the state of running ,the meter constantly modify the setting value (SV)according to the setting curve,make the measured value(PV) changing according to the curve program, so as to achieve the purpose of curve program control, and the indicator light turn bright.

State of interim :

When the meter is in the state of interim, the calculagraph stop timing ,the setting value(SV)maintain unchanged, and it also will prolong the running time of the curve program, the indicator light will coruscate.

State of automatic pause:

The state of automatic pause is the special form of the state of interim, created by the meter itself, not can be controlled by artifial. In the running state, when the deviation absolutevalue of themeasured value and present setting value(SV)>automatic pause strap (AL_P),the meter enter into the pause state,the indicator light will coruscate.,the calculagraph stop timing ,the setting value(SV)will not change. when the deviation absolutevalue of themeasured value and present setting value(SV)< automatic pause strap (AL_P),the meter will automatically resume the running state.

Hold state:

when the meter finish the curve program, and some section r=0时,the meter will enter into the hold state (run=1), and the main control output closed, the indicator light turn off, the below window display the first setting value. When the outer switch touch off or set the meter Run parameter to 3, it can restart.

2、Disposal on the power-cut

During the running process of the curve program,the meter will for every 5 minutes to save the running parameter and the running state data,so when the power is off and then on ,the meter only run according to the last saved data to continue ,

not from the beginning(if it need to start from beginning, press reposition key to start.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.